Profile

your printer

Module

Objective: At completion of this module you will be able

to profile

a printer utilizing given hardware and software tools.

We have already

covered monitors and scanners and although they are extremely important

to our workflow, the final destination for most image files will

most likely be ink on paper (print). Even though our monitor is

calibrated/profiled

along with our scanner if the printing process is not controlled

or understood you are most likely going to be very disappointed

with the results.

As we discussed

in Part I of this tutorial a profile describes the characteristics

of our device. Ideally we would like this profile to be as accurate

and precise as possible, because we want to match what we see on

our monitor to our output device, at least as close as we can get

it. In fact if your color devices have been properly calibrated

and profiled to this point your final output should come very close

to matching your original digital camera file or scanned negative/print.

Many printer and paper manufacturers have created and freely distribute

"canned" or generic profiles

for specific printer, ink and paper combinations. These profiles

are often used with fairly good results, some users however discover

that they are not good enough. There is a plethora of software

applications and hardware devices that can be used to create

custom profiles. A custom profile is created with

your specific printer, ink and paper combination for ultimate precision

and accuracy. This module will walk you through the process of creating

a custom printer profile.

Tools:

- Apple

G4 Computer OS 10.2.6

- GretagMacbeth

Eye-One Spectrophotometer

- Eye-One

Match software

- Epson

Stylus Photo 2200 Printer

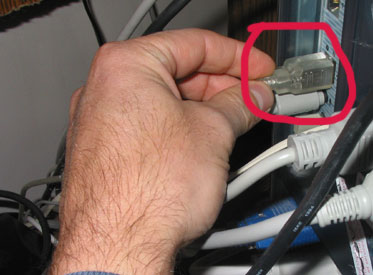

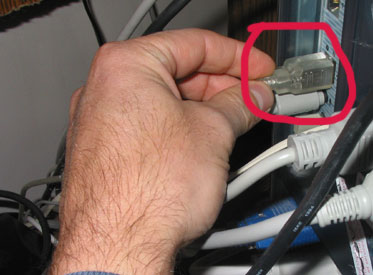

Step

1:

Attach Eye-One spectrophotometer

to your computer if you have not already done so.

Please

note that this device needs more power than can be delivered

from a keyboard USB connector. You will most likely need to

connect the Eye-One directly to your computer.

|

|

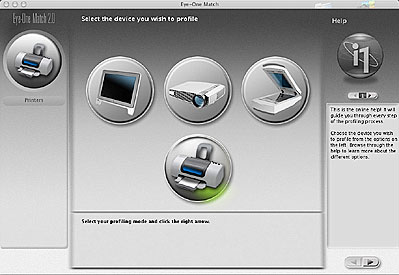

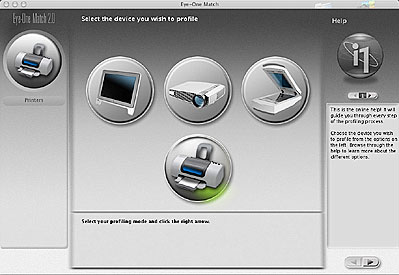

Step

2:

Open calibration/profiling (Eye-One Match) software

Select

Printer as the device to be calibrated/profiled.

|

|

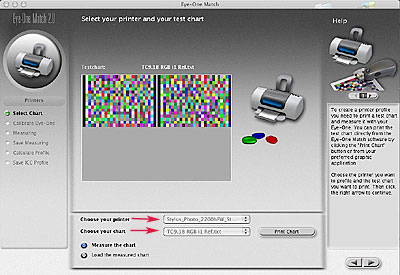

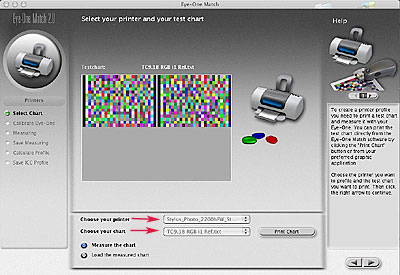

Step

3: Select

your printer and test chart.

In this

case we have selected the Epson 2200 (Ink Jet Printer) and

an RGB target with 918 color patches. Even though the Epson

printer uses CMYK inks it is best to treat it as an RGB device

for profiling. The larger target (918 patches) allows for

a more accurate profile.

At this

time you will also click on the Print Chart

button. This will take you directly to your printer dialog

box.

|

|

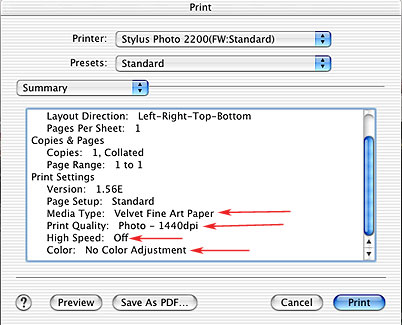

Step

4: Printer

settings...

From

the pull down menu on the left select Print Settings.

Select the Media Type that you are printing

too, IE: Velvet Fine Art Paper. Click on the Advanced

Settings button and select 1440 pr 2880 dpi for best

quality. Leave MicroWeave and Finest

Detail (checked) and High Speed

(unchecked).

The Media

Type is especially important as this will determine in part

how much ink is laid out on the paper. |

|

Step

5: Turn

the printers color management control off.

Select

Color Management from the pull down menu

on the left. Click on the No Color Adjustment button.

This will turn off the print drivers internal color management

control which is what we want. We want to control color via

our ICC Color Managed

workflow, the drivers attempt to manage color is not part

of this workflow and if on tends to create problems.

|

|

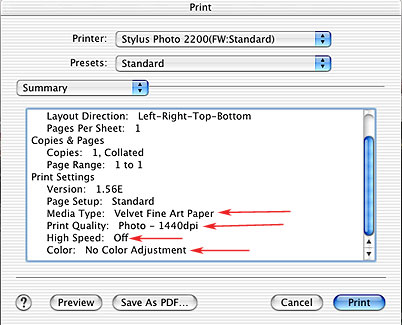

Step

6: Summary

of printer settings...

Select

Summary from the pull down menu on the left.

Look over the Print Settings and make sure

that they are set correctly before making your print. This

is just a good way to double check your settings before printing

your target file.

|

|

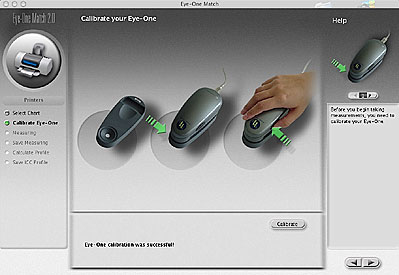

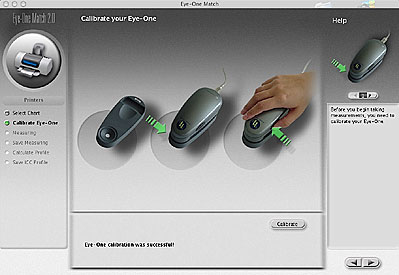

Step

7: Calibrate

the Eye-One Spectrophotometer.

Calibrating

the Eye-One spectrophotometer before reading color patches

ensures accurate data. Calibration

brings the device back to a known state. The Eye-One includes

a white calibration target on it's stand/holder. It is specific

to the SN# of the spectrophotometer.

|

|

|

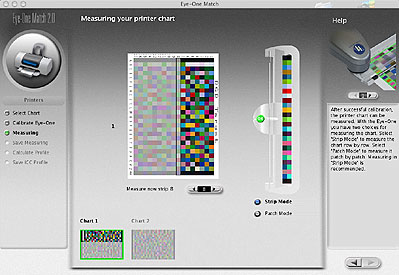

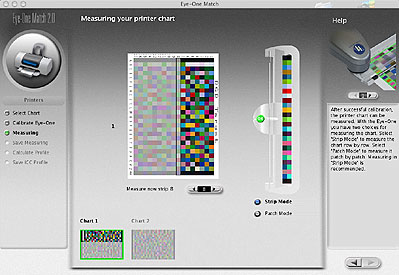

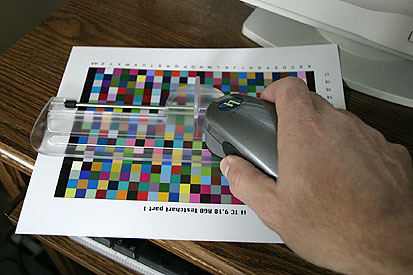

Step

8: Measure

patches..

You will

now measure all of the patches on the test target that you

printed. You have the option to read the patches one at a

time (very slow) or in strip mode. In this example we are

reading in strip mode. With the help of a plastic guide each

row is measured individually. The Eye-One is activated by

pressing the right hand button on the unit and slowly moving

over each row. Any errors will be noted and rows or patches

can be read again. |

|

|

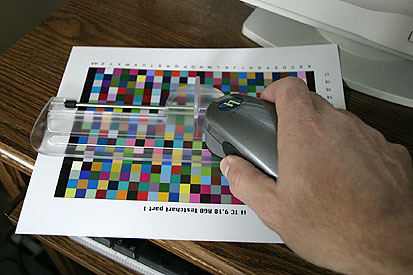

Step

8 continued...

Here's

an image that clearly shows how the rows of patches are read.

Remember move slowly from start to finish, the software will

note any errors it encounters.

|

|

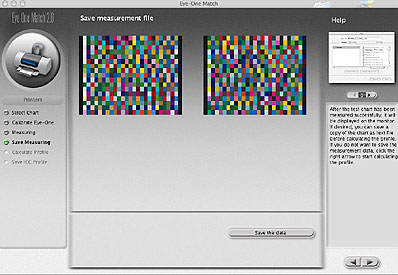

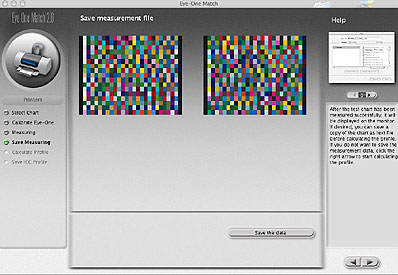

Step

9: Save

measured file.

Once

all of the patches have been successfully read, a measured

data (text) file can be saved. This text file can be opened

later and used to build a custom ICC printer profile or you

can skip this step and proceed directly to building your profile.

|

|

|

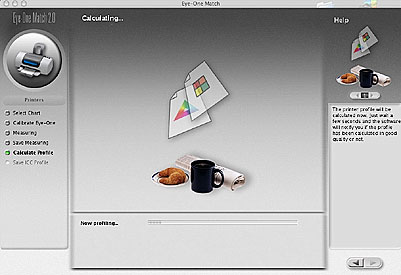

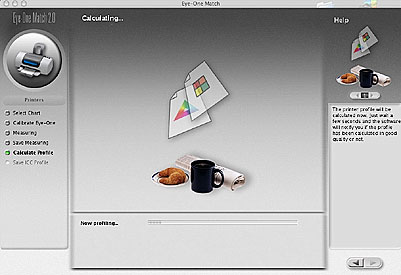

Step

10: Calculate

profile.

The software

will use the measured reading from your test target to create

a custom ICC printer profile. This profile represents the

color printing characteristics of your printer, ink and paper

set-up. A custom profile should be created for each printer,

ink and paper combination you plan to use.

This

is a processor intensive task and may take a few minutes.

|

|

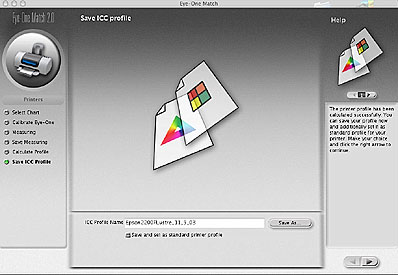

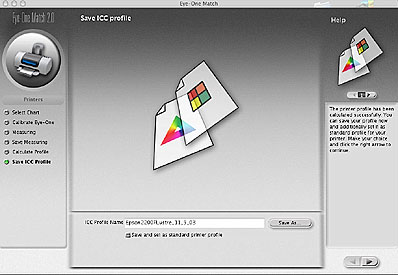

Step

11: Save

ICC profile.

This

is the last step in the printer profiling process. Save your

new profile with a name that makes sense. It is helpful to

include the printer name, ink and paper type in your description

along with the current date. This file will be placed in the

ColorSync folder within your operating system and is now ready

for use.

|

|

OK, you've

completed all but one module. You're well on your way to understanding

how to use and implement an ICC color workflow. Before you proceed

however please go through the following review questions to test

your knowledge.

Review

Questions: click

on the correct answer

1) The printer

target should always be printed with the default settings in your

print driver.

2) Even though

an Epson Ink Jet printer uses CMYK inks for printing it is best

to profile it as an RGB device with most profiling software packages.

3) You should

always profile your device (spectrophotometer) before any readings

are made from the printed target file.

4) ICC is an

abbreviation for the International Calibration Consortium.

5) Once you

create a custom profile with a particular printer, ink and paper

combination, in general you should not have to create another profile

for this set-up.

Great job...

your now ready to move on to the last module in this tutorial "Color

Management and Adobe Photoshop".

______________________________________________________________________________________________________

|